Impression coping are defined as the machined attachments that, connecting to the coronal part of the implant within the oral cavity and axially fixed by the impression screw, is used to make the transfer of the position of the implant in the biological medium to a laboratory model, on which the prosthetic will work to create the dental crowns or prostheses. This process is achieved using impression materials placed in an appropriate manner, that will harden in the oral cavity and produce the negative of the patient’s mouth. Once extracted, replicas are placed and the casting plaster is poured to obtain the positive mould where the replica will be placed in the original position of the implant in the mouth.

Key features

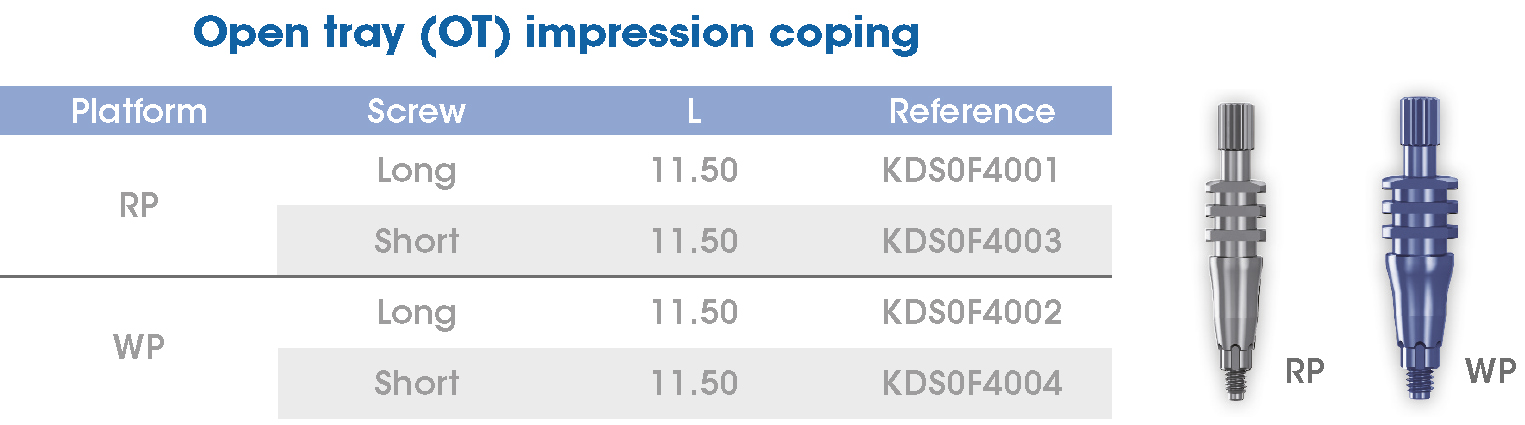

- Machined open tray impression coping in grade V titanium according to ISO-5832.

- Impression screws in grade V titanium according to ISO-5832.

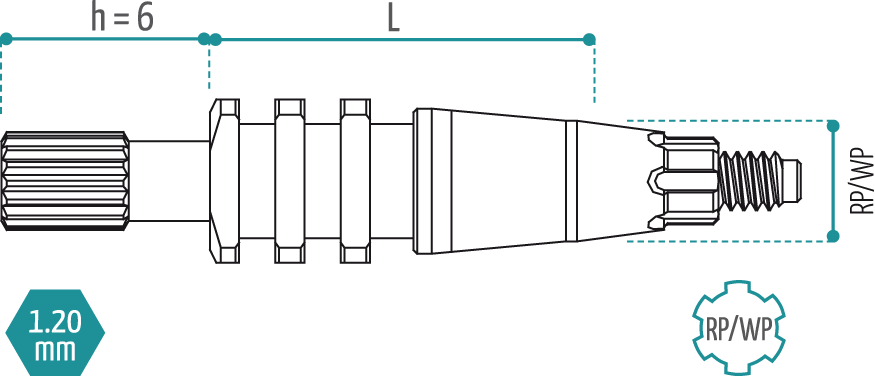

- Tightening of impression screws with b/f 1.20 mm hex wrench.

- Apical bit to facilitate the start of threading impression screw.

- Anti-rotation millings and vertical retention neck for a good fixation.

- Impression coping screw included.

- Long impression screw with longitudinal millings for manual tightening.

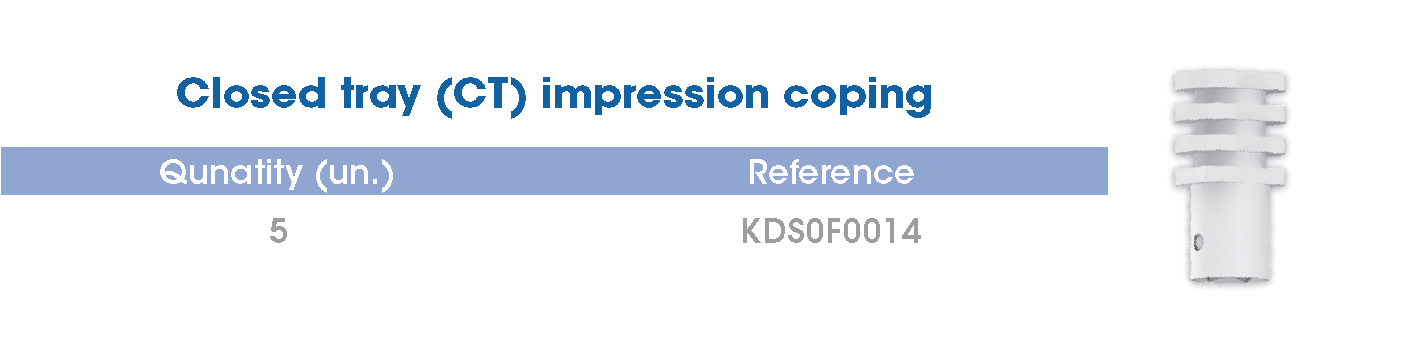

- Closed tray impression coping machined in technical plastic.

- Manual tightening torque: Máx. 15 N·cm.